What are the different materials for sneakers?

It is difficult to imagine the life of a modern person without such sports shoes as sneakers. Everyone in their wardrobe has at least one pair of sneakers for daily walks or for sports. Each of the models that is presented on the domestic market can guarantee reliability, comfort and beautiful appearance. You get all these benefits if you decide to buy sneakers, and you can wear them anywhere and everywhere.

People who play sports especially love sneakers, because... Without this piece of equipment, no athlete will be able to perform to their maximum, and the chance of injury also increases. But what provides all these advantages, what materials do manufacturers use when they develop the next pair of shoes for their fans.

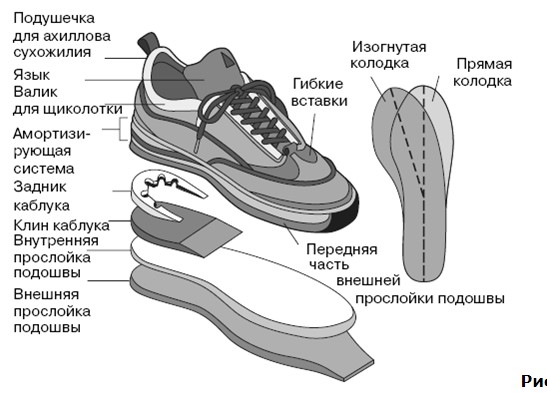

Upper part

It would be logical to look at the design of the sneaker from the top. It is this part that is intended to protect the foot, as well as to hold it on the intermediate part of the sole. To ensure maximum reliability and safety, various combinations of artificial and natural materials are usually used. There are three main categories of materials that are used to create the upper of sneakers:

- Genuine leather is an elastic, durable and breathable material that perfectly maintains its shape and can stretch and, conversely, shrink, depending on the conditions. Sneakers made of genuine leather are quite expensive. Suitable for creating sneakers for different seasons, especially for winter, autumn and winter;

- synthetic leather - when compared with natural leather, synthetic analogues have a lighter and stronger structure, and also do not have the ability to stretch or deform in any other way if external operational circumstances influence it. These sneakers are much cheaper than models made from natural materials;

- Mesh material is a lightweight, breathable material of synthetic origin, which is made from nylon or polyester threads, which will guarantee not only the light weight of the shoes, but also excellent air exchange inside. It will be an ideal solution for summer shoes.

And these are just three key materials, while each manufacturer strives to surprise its fans by offering unique developments. This contributes to the fact that every day more and more new and technological fabrics and materials appear that make it possible to achieve simply ideal performance. Only the end buyer benefits from such a war.

Midsole

This part of the shoe is one of the key components, because... It is she who is able to guarantee the stability of the leg, as well as absorb all loads and shocks. In the production of such soles, the following materials are most often used:

- Phylon is a lightweight foam that has excellent performance properties. It has a good shock-absorbing effect. Shoes are made from EVA granules, which allows you to create a sole of absolutely any shape, it all depends on the purpose for which the sneakers are created.

- Polyurethane is a hard, dense material that offers a high level of durability when compared to other midsole material options. It is the hardness that contributes to the fact that polyurethane has become less and less used not only in the production of the midsole, but also its main part.

- Filight is a unique tandem of rubber and phylon, which is a kind of “golden mean” between the materials listed above. They are typically used in the midsole along with the outsole, which makes it possible to significantly increase the level of elasticity of the sneakers, significantly reducing their weight.

- EVA is a relatively cheap foam material that is flexible and lightweight. It is usually used for entry-level sneakers, because... the air located inside the foam begins to be squeezed out over a certain period of time under the influence of the person’s weight, and the sole cannot return to its previous shape. This feature means that the material is rarely used for professional sneakers, but is suitable for everyday wear.

The midsole material is usually chosen depending on what purpose you need the sneakers for. For example, if for professional purposes, then running sneakers with filite are exactly what you need.

Main sole

It is the sole that is responsible for ensuring that the user can properly grip various surfaces and is the first level of shock-absorbing material. Thanks to various treads, the developers were able to adapt the sole to absolutely different types of loads, as well as the characteristics of a particular sport. As for the main sole, now manufacturers most often use:

- Clean rubber. It is a combination of several types of rubber of synthetic and natural origin. The most popular material used to produce soles for any type of sports shoes. It will guarantee excellent grip and durability - the main advantages. It is also worth noting the affordable prices for sneakers with rubber soles.

- BRS 1000. High-strength material, which is a rubber of synthetic origin, interacting together with carbon. Mainly used to make the base of running shoes. Suitable for athletes of various classes.

- DRC mixture. This is pure rubber, which contains an admixture of additives - the most reliable type of rubber that is not afraid of absolutely anything. This mixture would be an excellent solution for tennis or walking shoes.

- Duralon. It is another mixture of artificially created rubber, which is created by the blowing method. The disadvantage of such rubber is that it wears out quite quickly, while the composition contains special air pores, which will guarantee an excellent level of shock absorption. Cape area material is often used.

These are the main materials that can be used to create the sole. Likewise, everything depends on the needs of the athlete himself.

Fasels, laces and other details

Various fasteners and laces are usually made of synthetic fibers with plastic and metal tips. The Velcro goes well with the textile fastener, having small hooks on one side and loops on the other. Less commonly, various plastic and metal clips with carabiners and elastic bands with locks are used on sneakers.

Additional details include holes for laces and insoles. Insoles are usually made of padded material and may be glued to a backing or freely removable. Holes for laces can be plastic or metal.

As you can see, today there are a whole variety of materials with which you can create sneakers for absolutely any purpose for athletes and people who need comfortable and comfortable shoes. Despite the fact that there are already a lot of materials, manufacturers work every day to create something new and perfect. And our online store has made sure that you can buy sneakers and other shoes from famous brands on favorable terms, just call or leave a request on the website. Only certified shoes from manufacturers with delivery throughout the country: Kyiv, Odessa, Lvov, Nikolaev and other regions.